- Home

- Products

- Industry Laser Machines

- Laser Marking Machine

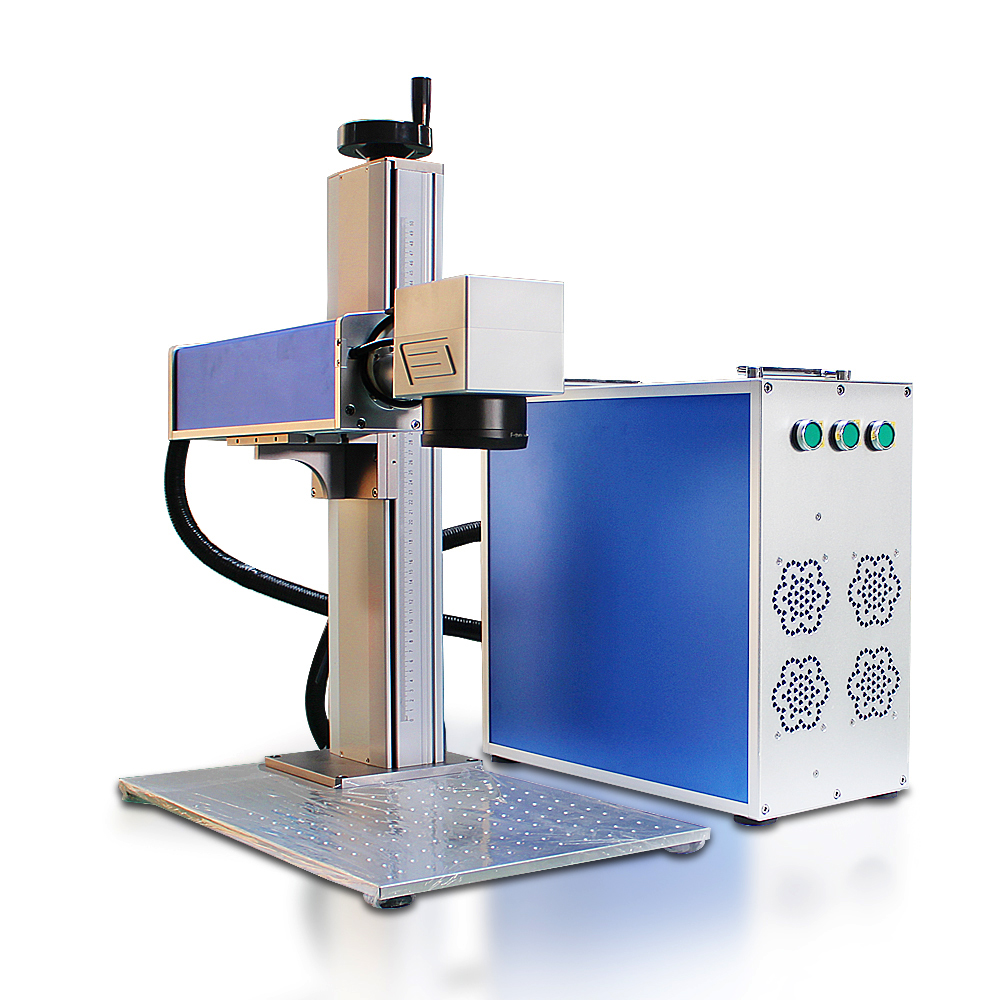

Laser Marking Machine

Description

Laser marking machine is using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.

Product Categories

Specifications:

| Laser Type (Wavelength) | 1064nm | 1.6um (10600nm) | 532nm | 355nm |

| Laser power | 20W/ 30W/ 50W/ 100W | 30W/ 60W/ 100W /150W | 5W/10W | |

| Supports graphical format | PLT, BMP, JPG, PNG, TIP, PCX, TGA, ICO, DXF… | |||

| Beam quality | M²<2 | |||

| Power stability | (8h) <± 1% rms | |||

| Pulse repetition frequency | 20KHZ- 100KHZ | |||

| Power consumed | <800W | |||

| Minimum line width | 50μm | |||

| Minimum character | 0.015mm | |||

| Marking area | 110*110mm to 1200*1200mm (optional) | |||

| Cooling system | Air cooling | |||

| Operating voltage | 110/220V ± 10% /, 50/60HZ | |||

| Operating temperature | 15°C - 35°C | |||

Introduction of Laser Marking Machine:

Application:

Electronic Components: Resistors, Capacitors, Chips, Printed Circuit Boards, Computer Keyboard, etc.

Mechanical Parts: Bearings, Gears, Standard Parts, Motor, etc.

Instrument: Panel Board, Nameplates, Precision equipment, etc.

Hardware Tools: Knives, Tools, Measuring Tools, Cutting Tools, etc.

Automobile Parts: Pistons and Rings, Gears, Shafts, Bearings, Clutch, Lights, etc.

Daily Necessities: Handicrafts, Zipper, Key Holder, Sanitary Ware, etc.

Applicable material: wood, paper, leather, cloth, plexiglass, epoxy, acrylic, unsaturated polyester resin and other non-metal materials.

Application Industries: Building, materials, beverage, pharmaceutical, tobacco, leather, packing, food, lighting, accessories, cosmetics, electronics and other industries.

- Products Industry Laser Machines Industry Laser Components Laser Beauty Machines Laser Beauty Compoments Other Products

- Contact Us General Manager: Kevin Zhang Mobile: +86 18701633869 Email: kevin.z@forelymed.com WhatsApp: +86 18701633869 Skype: kevin 2hang

- About Us SINOPER was founded in 2013 and is headquartered in Beijing, China. It is a high-tech enterprise specializing in the research, development, production, sales and service of laser applications. We have plenty of good talented staffs in the area of photoelectric, medical, clinical, domestic marketing and international marketing.

العربية

العربية Português

Português Français

Français Русский

Русский Español

Español English

English